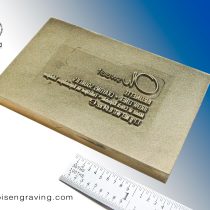

Illinois Engraving provides Hot Stamping Dies reproduced from artwork, drawings or instruct, in a variety of materials.

HOT STAMPING DIES

-

- For marking plastics and soft materials through foil.

- Engraved and fitted to match flat, curved or odd shape surfaces.

- We are equipped to provide fixturing for your press if required.

- Dies can be mounted on aluminum backing plates for additional height requirements.

- Dies made with cavity pockets can accommodate individual inserts or type for marking part numbers or logos.

HOT STAMPING DIE MATERIAL OPTIONS

STEEL

STEEL

- Tool steel material that is machined, engraved, hardened and ground.

- Appropriate for long running applications.

- Although the most expensive alternative, it would pay for itself with reduced downtime.

- Can be engraved to fit contoured parts.

BRASS

BRASS

- Machine engraved.

- Similar properties to steel except about 25% less expensive.

- Better heat transfer than steel but not nearly as durable.

COPPER

COPPER

- Photo etched from artwork.

- Good application for ornate graphics since the etching process is faster than mechanical engraving.

- Heat transfer similar to brass.

- Durability similar to brass.

- A limiting factor is that they can only be etched .040″ deep, although open areas can be machined deeper.

![]() MAGNESIUM

MAGNESIUM

- Photo etched like copper.

- Magnesium dies will transfer heat as well as copper or brass.

- It is the least expensive die material, but also the least durable metal.

Three thicknesses of magnesium are available.

- 1/4″ thick (.250″ thick with .080″ – .125″ etched relief)

- 11 point (.156″ thick with .060″ – .080″ etched relief)

- 16 gauge (.062″ thick with .035″ – .045″ etched relief

STEEL

STEEL COPPER

COPPER MAGNESIUM

MAGNESIUM